Understanding the vapour pressure of chemical compounds in the ultra-low range of 1–0.001 Pa (0.01–0.00001 Torr) is critical for industrial hygiene, chemical safety, and product development. LCS Laboratory Inc. specializes in highly sensitive vapour pressure measurements, offering precise testing services that meet the needs of Canadian safety and industrial professionals.

The Purpose of Our Vapour Pressure Testing

Vapour pressure testing is essential for understanding the behaviour of volatile compounds, especially in safety-critical environments such as pharmaceutical manufacturing, chemical production, and environmental monitoring. By determining the vapour pressure of your material, we provide data that supports compliance with safety regulations, enhances hazard communication through accurate Safety Data Sheets (SDS), and guides safe handling practices.

Technical Details of Our Testing Service

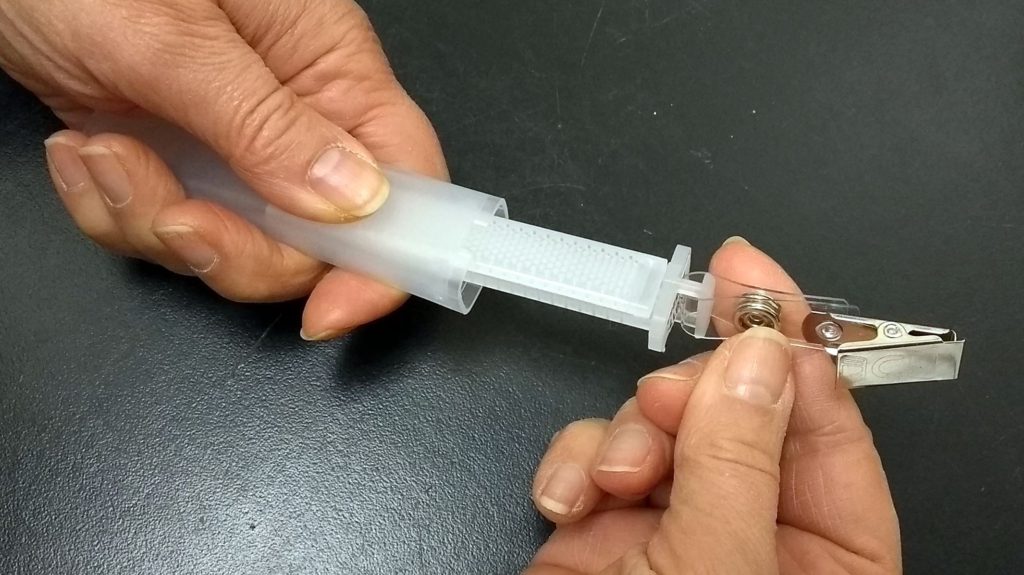

LCS Laboratory Inc. uses the OECD Method 104 – Vapour Saturation Technique to measure vapour pressures in the range of 0.0001 to 1 mm Hg at room temperature. This method involves saturating a dry air stream with the test compound’s vapour until equilibrium is reached. The saturated vapour concentration is then measured using NIOSH or OSHA-standard air testing methods. The results are recalculated into vapour pressure using standard conversion formulas. Our method has been validated with n-Hexadecane as a reference material, achieving a sensitivity of 0.004 Pa at 21 °C. Enhanced sensitivity is possible for compounds with aromatic or fluorescent groups.

Sample Requirements:

- Quantity Needed: ~500 mg of a neat material.

- Stability: Samples must have a half-life in air of at least one week.

- Documentation: Clients must provide the molecular weight (MW), SDS, solvent preferences, analytical conditions (GC or HPLC), and any applicable toxicological data.

Restrictions:

We do not accept highly toxic or radioactive materials for this test.

Why Choose a Canadian Testing Laboratory?

Partnering with a Canadian laboratory like LCS Laboratory Inc. offers several advantages:

- Expertise Tailored to Local Regulations: Our services align with Canadian health and safety standards, ensuring compliance and reducing the risk of costly oversights.

- Efficient Communication: Located in Canada, we’re in your time zone and can quickly respond to your needs.

- Cost-Effectiveness: Avoid the delays and additional shipping costs associated with overseas testing labs.

- Support for Canadian Industry: By working with us, you contribute to the growth of Canada’s health and safety community.

Contact Us

Ready to move forward? Email us to receive a non-obligatory quote. Include the following details for each sample:

- Number of samples.

- SDS or chemical formula, CAS number, and toxicological data.

- Material application (e.g., pharmaceutical, polymer, pesticide).

- Estimated boiling point and molecular weight (MW).

- Solvent preferences and analytical conditions (GC or HPLC).

- A statement confirming that the material is non-toxic and non-radioactive.

Discover more about our material testing services on our Material Testing Page. For accurate, professional results you can trust, LCS Laboratory Inc. is here to assist. Email us today!